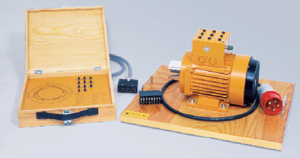

FAULT SIMULATION SYSTEM FOR AN INDUCTION MACHINE

MV 1046 3-Phase Squirrel Cage Motor with Fault Simulator

The equipment MV 1046 comprises :

1 3-phase squirrel cage motor

1 Fault simulator

1 Plug-in device

1 Insulated cable 4 x 1.5 RDV

1 Technical description with instructions for fault switching positions.

Motor

The motor is a standard, 3-phase squirrel cage induction motor (MT 80 A) of which the windings are fi tted with outputs to allow fault simulation. These outputs are connected to a terminal with a multi-pole socket.

Fault Simulator

The fault simulator, which comprises a wooden box with a lid and a built-in panel with 11 switches to simulate different faults, has a cable trunk fi tted with a multi-pole plug. This plug is intended for connection to the multi-pole socket on the motor´s terminal. This connection connects the switches of the fault simulator to the windings of the motor.

Plug-in Device

The fault simulator can be disconnected and replaced by a plug-in terminal device. The motor will then operate normally.

Insulated Cable

The insulated cable is used for the simulation of failures in the input voltage. The equipment is particularly well suited for fault fi nding exercises with squirrel-cage induction motors. The following types of faults can be simulated: phase failure of supply voltage, open-circuit winding, short-circuit winding and earth fault.

General Data MV 1046

Supply voltages 380-415 V 3-phase

50 / 60 Hz

Power 0.55 kW

Dimensions Fault Simulator 290 x 270 x 55 mm

Dimensions Motor 270 x 150 x 205 mm

Weight 13 kg

SINUMERIK 802S base line ,

Is the CNC from Siemens for lowest-cost applications provides a supreme answer to all questions thanks to three impressive points concerning turning and milling:

- Extremely simple operation

- No maintenance

- Unbeatable value for money.

The SINUMERIK 802S base line is designed for a maximum of three stepper feed axes and one analog spindle. We supply the operator panel control together with all components required, such as NC, PLC, operator panel, machine control panel, the relevant inputs, outputs and software.